Personal tools

Help

Tools

Class Notes

- Do you have news for fellow WSU alumni and other readers of Washington State Magazine? Send us your class note.

Our Story

written by alumni, faculty and friends.

NOTE: THIS IS A LEGACY SITE AND IS NOT REGULARLY MAINTAINED

Views

WSU Meats Lab New and Unique - HillTopics, 1970

From Our Story

HillTopics, November 1970

By Norma Sampson, Cooperative Extension

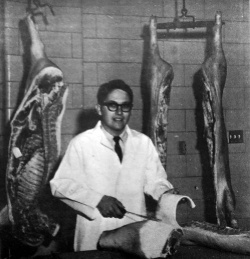

Washington State University has something no other university in the country has—a Meats lab. The newly constructed brick building provides facilities for processing eggs, poultry and red meats under one roof.

Red meat research can benefit from poultry technology, Dr. Everett I., Martin, WSU assistant professor of animal sciences and assistant animal scientist in charge of red meats research at the laboratory, said. “It has been just recently that commercial processing plants were allowed to handle poultry and red meats in the same place. We feel that if housed together there will be a give and take situation: The poultry people can take advantage of some of the livestock processing techniques and vice versa.”

Because of the sequence of fund allocations, the WSU meats laboratory is being built in two phases, Phase I is functional now; Phase II is under construction with completion date scheduled for August 1971.

“The total project cost for Phase I was $390,000 and for Phase II is $466,000,” Earl Muir, WSU facilities planning staff architect, said.

The 7,015 square feet Phase I building houses the red meats kill laboratory, locker rooms, toilet and shower facilities and the holding pens. Phase II, which will have 8,802 square feet, will include three elements: (1) poultry slaughtering and egg processing; (2) red meats research facilities for cutting and freezing; and (3) joint (poultry and red meats) facilities for smoking, curing processing and customer acceptance.

Muir, who has served as coordinator between the building committee and architect since 1967, said the department of animal sciences has had the entire building project in mind for some time. “Plans for the meats laboratory were being formulated before 1965, which was when the primary request for funds was made. Definite plans for Phase I began in the spring of 1967; Phase II began taking shape In the spring of 1969.”

“In planning and building the laboratory, we had to consider that it was not really a commercial meat packing plant but an educational plant,” Dr. Spencer said. “State and federal meat plant regulations are aimed primarily at commercial plants. Therefore, we had to make some interpretations of state and federal rules since it is an educational plant. However, in doing this we had excellent cooperation from the Washington State Department of Agriculture and USDA.”

The laboratory does meet state and federal inspection requirements for sanitation, Muir added. The problem was in making the laboratory flexible enough for instruction but at the same time meeting state and federal standards which are designed to protect the consumer.

For example in the kill areas, slaughtering will occur only as needed for research purposes or for two or three classes and not all the time, every day, as it would in a commercial plant, Dr. Martin said. “Slaughtering will be slow as we are not concerned with the number of animals per day which we can process. Also, since WSU teaches a course in slaughtering, we will be using inexperienced student help. Therefore, as far as we are concerned the facility is designed and meant to be an instructional model.”

The egg processing area of the Phase II building will house the egg breaking laboratory where yolks and whites will be separated and pasteurized and/or used in frozen egg products. Dr. Spencer is interested in the functional process of eggs. “For example, we may feed hens different fats and feeds such as fish meal in order to study the end quality and composition of the egg. Our research will include the dietary difference these feeds make and also the performance of the eggs in cakes and meringues,” Dr. Spencer said.

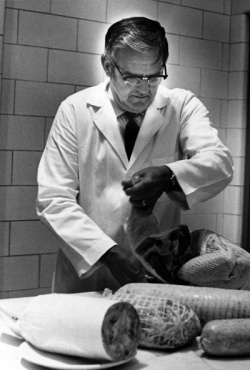

Meanwhile, in the research-cutting room of the Phase II building, Dr. Martin will be measuring the desirability of various carcasses. He plans to study, among other things, the ratio of lean to fat, of lean to bone, dressing percentage and the quality of lean tissue in terms of marbling. He also will be attempting to evaluate in the carcass the effects of various feeding and breeding aspects and management practices. “We are especially concerned today with the concept of efficiently producing quality protein or feed and not just raising various types of livestock,” Dr. Martin said.

Both Dr. Spencer and Dr. Martin plan to work with the technological area of new meat products. They will be testing the acceptability of new products in the consumer acceptance room of the Phase II building. “We are interested in the fundamental technological aspects of products. For example, we want to know how to make products more stable during chill or frozen storage or, in other words, how to keep them from spoiling and/or deteriorating,” Dr. Martin said.

Poultry and red meats will share cooking, processing, smoking and curing facilities in the Phase II building. Meats will be cooked in the research kitchen, and the final product’s flavor, taste, tenderness and juiciness will be evaluated and studied by a trained taste panel. Provisions have been made for a future smoke house.

Also, plans have been made for closed-circuit TV, Dr. Spencer said. Rough-in conduits for origination of TV from Phase I and II buildings will allow the department of animal sciences to install TV later whenever funds are available. There are presently two camera stations situated in the red meats kill laboratory and plans include a camera and monitor station for each section in the Phase II building. This would mean a total of seven stations with allowances for two cameras per station.

“The closed circuit TV will be used in meat classes in the new WSU animal sciences building,” Dr. T. H. Blosser, chairman of the WSU department of animal sciences, said. “Future plans will allow two-way voice communication so the course instructor will be able to direct from the classroom or from the meats laboratory.”

The new meats laboratory not only meets WSU’s present demands but also provides for the figure, Dr. Blosser said. “Putting the poultry and red meats together is in keeping with today’s trend in commercial plants and also will benefit the students. The WSU meats laboratory is a much needed facility as all department of animal science students and many food science majors will receive training there.”

Read about Cougar Smokies Brand sausages in "The Meat of the Matter" in the Fall 2010 issue of Washington State Magazine.

Our Story site map

Our Story main page | Our Story categories | Help Desk

Contact | Give | Advertise

Washington State Magazine | Washington State University | Class Notes

Our Story is coordinated by

In partnership with

Our Story and Washington State Magazine are publications of Washington State University. All rights reserved.

P.O. Box 641227, Washington State University, Pullman, WA 99164-1227 USA | wsm@wsu.edu, 509-335-2388

Accessibility | Copyright | Policies